It’s great to see trade shows happening again, especially with so many rescheduled from earlier in the year being added to Q3 and Q4 of 2021.

Since rolls of trade show flooring have sat dormant in warehouses all over the country for the past 14+ months, there is a chance your flooring might not be exactly how you left it. As your flooring partner, we wanted to pass on some things that your warehouse team should look for on your racks to help avoid any long term damage, as well as the dreaded show floor surprises, which we all hate.

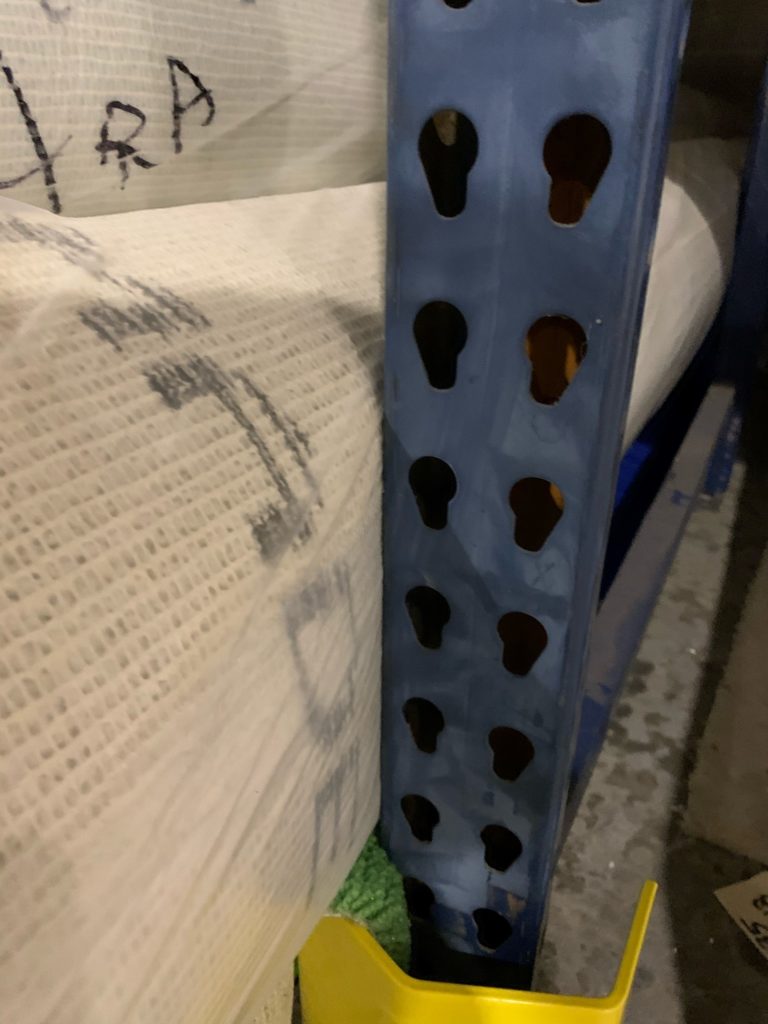

The attached photo shows a roll of carpet wedged against a side rail of a rack, as well as a roll of vinyl that has started to compress by the heavier rolls stored on top of it. Here’s how to fix both of these issues.

How to Fix Compressed Carpet

In both instances you’ll need to unroll the flooring and do a visual inspection. If the carpet pile has lines on it that appear to be a different color, it’s usually because the fibers have been crushed. This can often be easily fixed by vacuuming over the affected area, which will allow the fibers to relax and return to their previous state. For extreme situations, using a carpet cleaning machine without detergents will help bring the carpet fiber back to life. Once the carpet is dry, make sure you reroll the carpet on a cardboard core, this is a two person job to make sure that the carpet is rolled tight.

How to Fix Compressed Vinyl

If a roll of vinyl is starting to flatten, rolling it out and letting it sit in a hot environment will allow it to relax after a day or two. Once the vinyl lays flat, you’ll just need to reroll the vinyl tightly onto a core and return it to storage. For any particularly lumpy areas, you can use the core like a rolling pin to expedite the flattening process.

You’ll want to make sure heavier rolls of carpet are stored on the bottom of your flooring rack, and it’s a good idea to rotate them every month or so to help avoid lumps from forming.

A 10’ long or 12’ long roll of flooring stored over the edge of an 8’ long rack will start to bend over time. If your carpet storage racks are only 8’ long, either add another section to the rack or store those rolls on the warehouse floor as an alternative.

Our hope is that the flooring you’re storing is in perfect condition, but if your team has any questions about flooring that you’ve been storing they can reach Dave Sterne directly at 404.867.2144 or by email at dave@theinsidetrackinc.com

Contact Us

Ready to get started? Our experienced team can answer your questions, start your order, or ship samples right to your door.